Plastic Film

Market demand for plastic film is higher than ever before. Plastic film is widely used across a variety of industries — from packing and shipping, to everyday consumer products like adhesive tape, candy wrappers and beverage containers. Plastic film is also used in specialty electronics manufacturing, such as liquid crystal panels (LCD) and secondary batteries. Since demand is high, manufacturers seek quality engineering and components in their equipment. Ensuring that a plastic film stretcher can perform reliably and efficiently can improve overall operational efficiency and save costs.

What Is a Tenter Clip?

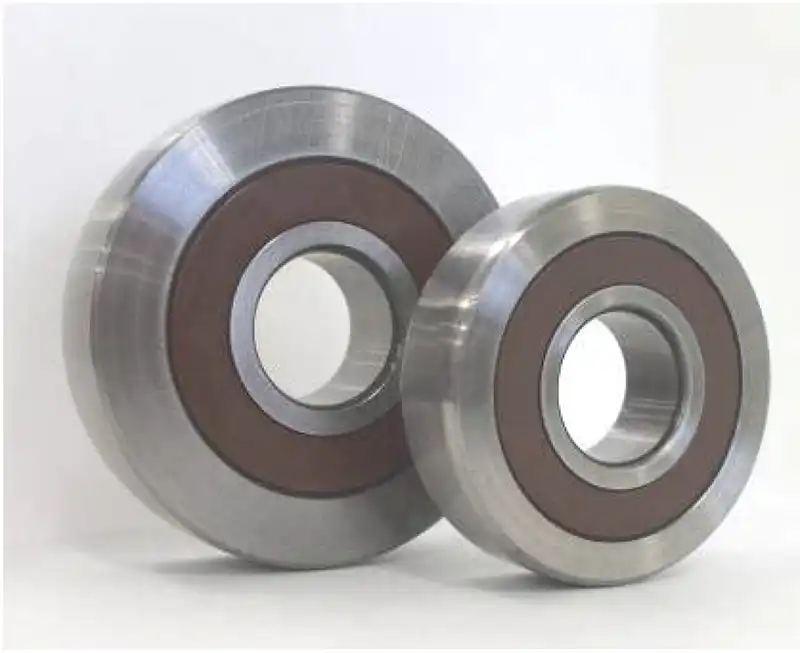

An essential component of a plastic film stretcher is the tenter clip, a mechanism that clamps onto the edge of a plastic film and helps guide the sheet of plastic through the stretcher. A typical plastic film stretcher would have hundreds or even thousands of these tenter clips to maintain stability and accuracy during the stretching process. Tenter clips are attached to a chain and utilize single and double roll ball bearings to guide them along a monorail line through the production process. To achieve the desired final product specifications without unnecessary slowdowns, plastic film stretchers require precise manufacturing processes.

What Are the Benefits of Tenter Clip Bearings?

Heat Stabilization and Leakage Resistance

Plastic film stretching machines run at high speeds in high-temperature environments. The grease in many types of other bearings can leak at these high temperatures, slowing down production and contaminating the final product. SMT tenter clip bearings have special dimensions and are specifically designed to perform at high speeds. The product’s unique design lends to the following high heat characteristics:

- Steel construction

- Optimized internal clearance

- Fluorine rubber seals

- Fluorine grease for increased heat stabilization and leak resistance

Increased Operational Efficiency

These quality tenter clip bearings enable plastic film manufacturers to keep their machines in operation at higher speeds, for longer periods, with fewer maintenance checks or shutdowns. In addition to heat stabilization, the fluorine rubber in the SMT tenter clip bearing also minimizes vibration, creating more reliable results without putting undue pressure and friction on the manufacturing equipment. Overall, this leads to higher production and lower operational costs.

Contact Our Team Today

At Ritbearing, our team has more than 40 years of experience supplying OEM-approved bearings for tenter frame applications. We can work with you to find and source high-quality tenter clip bearings from the world’s leading ball-bearing manufacturer, SMT. As an industry leader, SMT produces quality bearings that will keep your plastic film stretcher operating smoothly and efficiently.

Ready to get started? Request a quote from our friendly team of experts today.