High Performance, Lasting Bearings

Solid lubricant bearings are quickly becoming a popular solution for a range of bearing issues. JNS’ S Lube Needle Bearings, Cam Followers, and Needle Roller Bearings are all compatible with solid lubricant to create high performance, lasting bearings.

How JNS Solid Lubrication Needle Bearings Work

Ritbearing is proud to be the primary importer of JNS bearings products in the U.S. JNS continues to innovate their bearing products to meet the needs of the industry and solve our customers’ bearing performance issues.

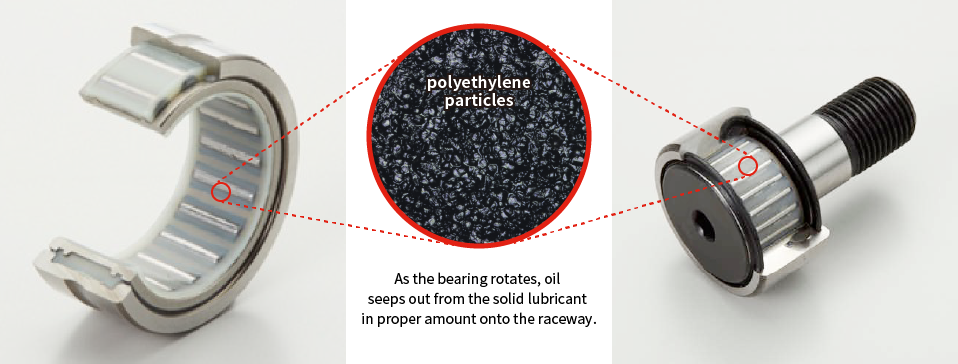

JNS S Lube Needle Bearings are bearings designed with a solid lubricant formed directly into the bearing and are available in standard or stainless steel, depending on your application. The JNS lubricant is made of a combination of a high quantity of lubrication oil and ultra-high molecular weight polyethylene that are mixed and solidified under extreme heat application. As the bearing rotates and produces heat, the oil releases from the solid lubricant to continuously coat the bearing to minimize heat damage and ensure efficient movement.

What Are the Benefits of Solid Lubrication Bearings?

In general, solid lubricant bearings allow for increased service life, consistent available lubrication oil, and proper quantities of lubrication oil for the bearing, regardless of its application. The main characteristics of solid lubrication bearings that help to increase bearing performance are:

- Durable Stainless Materials

- Minimal Environmental Impact

- Increased Protection Against Contaminants

- Maintenance Free

Solid lubrication bearings eliminate the need for manual maintenance and relubrication, and end the risk of grease incompatibilities in manual work. Because maintenance is no longer required, employee risk is reduced for bearings used to harsh environments and those remaining resources can be better allocated to other business needs. This helps to reduce operating costs for businesses in general and improve process efficiency.

The solid lubricant fill also acts as an additional seal system for the bearing, reducing the risk of contaminants entering the bearing, which in turn increases the bearing lifespan and effectiveness. Even though the oil converts back to a liquid form when the bearing is in operation, the polymer material remains a solid to block particulates from the interior of the bearing to prevent damage.

JNS Solid Lubrication Cam & Roller Followers

JNS manufactures Cam Followers and Roller Followers in both standard and stainless steel materials to meet the requirements of every application. While the JNS Needle Bearing design has a separable inner ring, which would allow a secondary company to add a solid lubrication fill to the bearing, the JNS Cam Follower and Roller Follower design is different.

Due to the design and construction of the JNS Cam Followers, having a rework facility add a solid lubrication fill would be extremely difficult. Standard JNS Cam Followers are lubricated with high quality lithium soap-based grease, grade 2 which are RoHS compliant and ready for immediate use. For applications in environments with an increased risk of bearing contamination or damage, Cam Followers are available with seals comprised of synthetic rubber with high abrasion resistance.

JNS Roller Followers are designed with a non-separable inner ring (NART & NURT type) and a separable option (NAST type and RNAST type). Like the Cam Followers, standard Roller Followers are also lubricated with the same high quality lithium soap-based grease, grade 2 and ready for use. Roller Followers are also available with additional seals to increase bearing protection against contamination to reduce wear and increase part lifespan.

Ritbearing is a proud distributor of JNS bearings. JNS solid lubrication bearing options provide solutions that increase bearing efficiency and lifespan that also reduce bearing wear and employee risk.

Want more information on JNS solid lubrication bearings? Contact us today!