Time is not always on your side in business. Wasted time can mean wasted money, so prioritizing efficiency is very important, especially when it comes to your warehouse.

The good news is that there are plenty of ways to increase warehouse productivity, and because 60% of your warehouse workforce spends time getting to or moving product, it’s easy to know where to start if you want to move more product faster.

AUTOMATION IS KEY

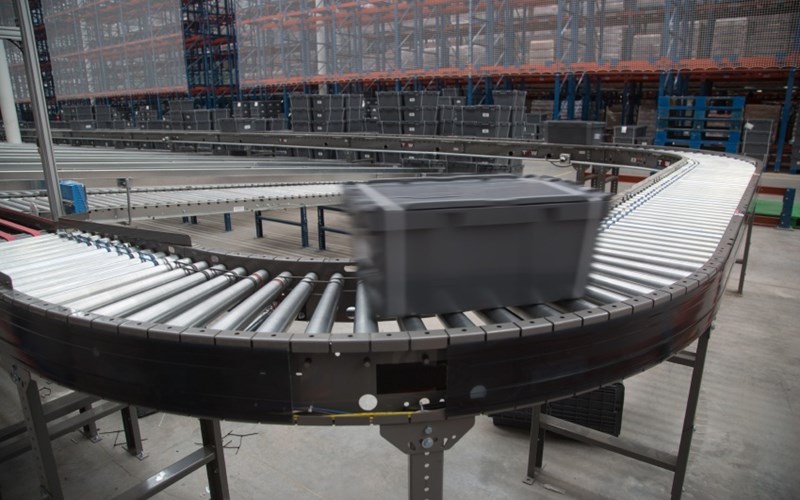

Automation is a hugely important topic because it significantly cuts down on all that wasted time. It covers anything from cranes to PLCs (programmable logic controllers), logistics automation software to automated storage and retrieval systems, and, what we will talk specifically about in this post, conveyance systems.

HOW BEARINGS IMPACT WAREHOUSE PRODUCTIVITY

Conveyance systems improve warehouse processes in a number of ways. They free up floor space, enable your warehouse to scale up more easily during peak order season, and decrease order fulfillment time, and more.

Unless it stops working the way it was intended.

One of our bearing manufacturer partners, RKB, released a study back in 2010 about the most common causes of bearing failure.

That study found that inappropriate bearing lubrication, improper bearing selection, and improper mounting accounted for 95% of all bearing failures. In other words, 95% of bearing failure is the result of human error.

Now, as you can imagine, there are a lot of bearings in a conveyor system. If they don’t work the way they were intended, or if they aren’t properly maintained, you’re going to have unnecessary downtime, and you won’t fully realize all of the benefits listed above.

CHOOSE THE RIGHT BEARING SUPPLIER

Regardless of whether you need help choosing the right bearing or you need help developing a customized maintenance program, our engineers can help you find a solution that improves your warehouse’s productivity. To learn more, give us a call at 1-800-431-1980 or fill out our quote form today.