Angular contact ball bearings are a type of rolling-element bearing. As the name implies, rolling-element bearings use a roller or ball to carry a load.

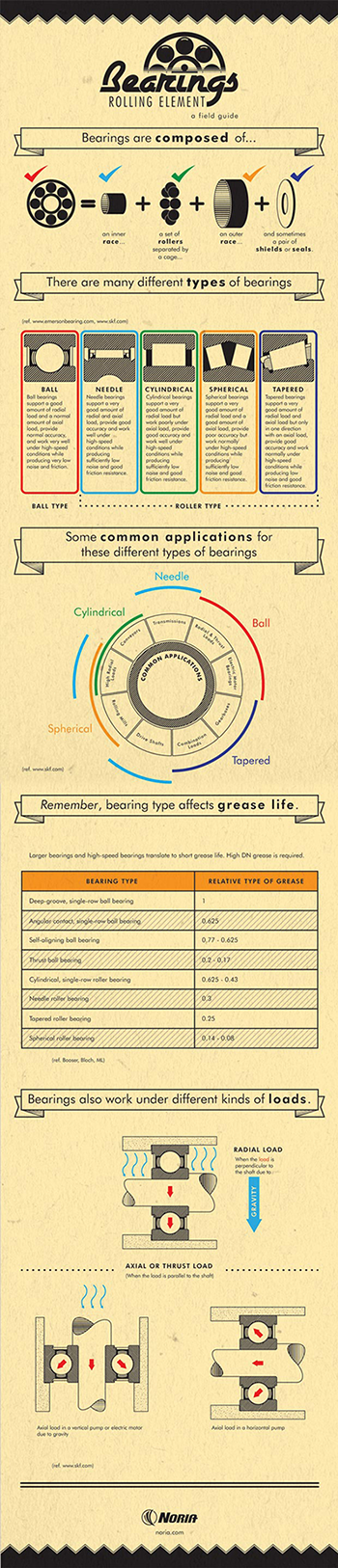

There are many types of roller-element bearings, including:

- Needle

- Cylindrical

- Spherical

- Tapered

- Ball

Each type of bearing has its own distinct advantages and trade-offs. To get a better idea about these differences, take a look at the infographic below.

TYPES OF BALL BEARINGS

There are three types of ball bearings: angular contact (which we’ll discuss shortly), axial, and deep-groove.

Regardless of the type of ball bearing, their purpose is to reduce rotational friction and all are able to support both axial and radial (or thrust) force.

For reference, bearings move around a fixed axis. Depending on the application, a bearing may be subject to axial force (force that is applied parallel to the axis) or a radial force (force that is applied perpendicular to the axis), or both.

Because not all bearings are able to support both forces, ball bearings are quite versatile and are among the most-used type of rolling-element bearing.

ANGULAR CONTACT BEARINGS

Angular contact bearings are ideal for use in gearboxes, pumps, electric motors, and clutches or other high-speed applications.

They are commonly used in the Materials Handling, Machine Tool, Steel Mill, and Wind Energy industries.

Although angular contact bearings can accept thrust loads in only one direction, they can be manufactured at different contact angles (usually between 0 and 45 degrees) to transfer the load acting upon the bearing.

Here is what an angular contact bearing looks like:

CONTACT US

We hope this post has helped you better understand the role of ball bearings and, more specifically, angular contact ball bearings. If you would like more information about angular contact ball bearings, please feel free to contact us. You can do so by filling out our contact form, calling us 1-800-431-1980 or by visiting our angular contact ball bearings page.

Source: Machinery Lubrication