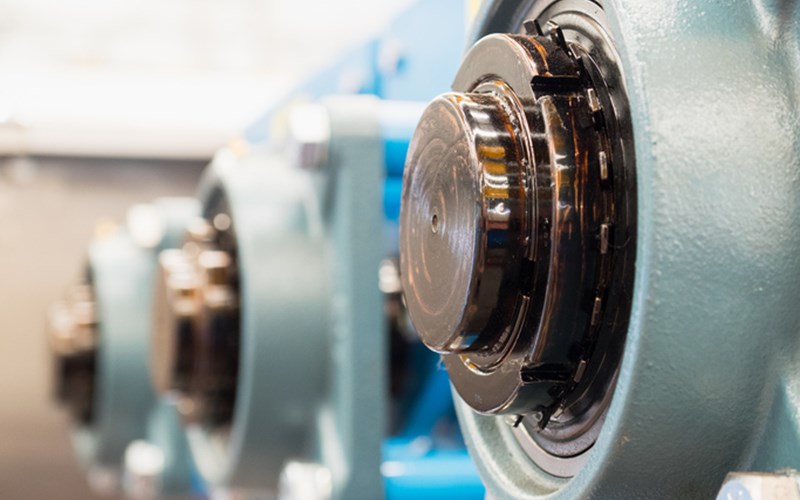

A good bearing lubricant can help extend the life of your bearings. However, improper use or handling of bearing lubricants can lead to problems for your applications.

In order to make sure your bearing lubrication standards are up to snuff, you need to have the right information. Here are three myths about bearing lubrication that you shouldn’t believe.

ALL LUBRICATIONS ARE THE SAME

Not all lubrications are created equal. There are many different types of bearing lubrications and each one can have different benefits. General grease is the most common option, but there are others, including:

- Oil lubricants

- Solid lubricants

- Graphite

- Specialized plating

There’s also an issue where certain lubricants may not be compatible with each other, leading to thickening or thinning that can lead to more wear and tear for your bearing. Other types of lubricants can pair well together, like oils and solid lubricants. Keep these factors in mind when deciding bearing lubricants, because replacing one with another without checking can lead to problems in the future.

RE-LUBRICATION IS AN ANNUAL EVENT

Odds are, you’re going to have to re-lubricate your bearings more than once in a year. Your re-lubrication schedule will be impacted by a few factors, including how much your bearings are used and the environment of the application.

Heavier use and harsher elements are likely going to mean more frequent re-lubrications, perhaps even as often as one per week. If the bearings are lightly used and operate in ideal conditions, it’s possible re-lubrication can be done on an annual basis. Either way, it’s important to set up a regular lubrication schedule to make sure that your bearings are always good to go.

LUBRICATION CAN BE STORED ANYWHERE

This depends on the state of your storage area. Lubricants can be easily contaminated, so they need to be stored in places that won’t collect dirt, dust, or any other substances that can ruin your product. You can’t use contaminated lubrication, so it can pay to find the perfect place to store it and keep it safe from contaminants.

KEEP YOUR BEARINGS PROPERLY LUBRICATED

Good lubrication can extend the life of your bearings, allowing your applications to run smoothly for as long as possible. Of course, good bearing lubrication won’t be able to do much without the right bearings.

As a premier bearing supplier, our experts can help you find the right parts for your applications and help you match your bearings with the right lubrication options. Contact us today to talk to our team about your bearing needs and questions.