From clocks and sewing machines to firearms and automobiles– these are all industries that helped spur machine tool development.

The manufacturing of metal parts and components is an essential process in any marketplace, and machine tools are used for this purpose across industries.

The United States used to be the dominate producer in machine tool manufacturing, but during the 1980s and 1990s lost major ground to companies from Germany, Japan and Italy.

Today companies from countries like Taiwan and China have started to gain market share. So it’s safe to say that If you’re buying parts for this industry, you’ll have options from all over the globe.

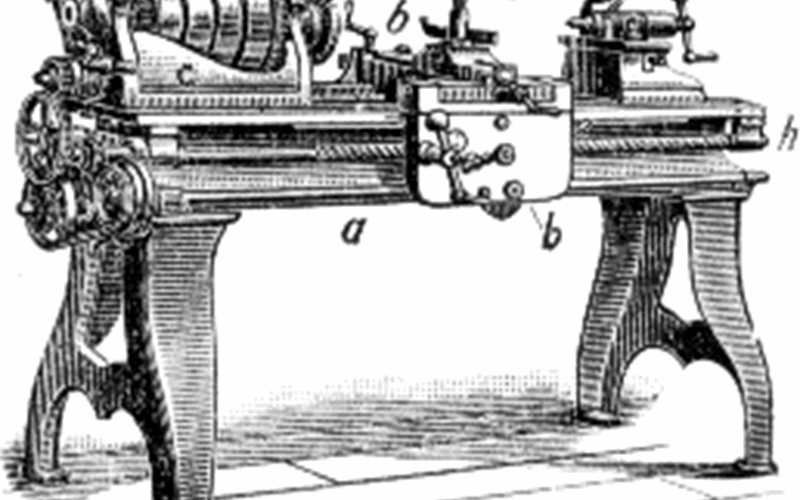

Photo Credit: A metalworking lathe from 1911 showing component parts

WHAT DO MACHINE TOOL DESIGNERS LOOK FOR?

Machine tool designers seek reliable, quality components that can perform or exceed required standards and strengthen their company’s image in the marketplace. And because these machines typically run for 24 hours a day, downtime severely affects production and results in lost revenue.

That’s another similarity across the industries– no one wants to lose money. So to prevent downtime and save money, companies can invest in quality components with features that support their unique application.

We’ve started a list of features and bearing applications for the industry below.

MACHINE TOOL BEARING FEATURES

PRECISION ANGULAR CONTACT BEARINGS

- High stiffness

- Ability to carry axial forces in one direction

- Tolerance typically in the Abec 7 to Abec 9 range

- Non-separable

- Can be provided in a single fashion, pairs, tri-sets or quad sets

PRECISION CYLINDRICAL ROLLER BEARINGS

- Supplied in either single or double row

- Single row design is ideal for higher speed applications

- Double row design is ideal for higher rigidity

- Rolling element allows for higher load carrying capacity throughout the bearing

- Can be offered with a tapered bore design

BALL SCREW SUPPORT BEARINGS

- Precision angular contact ball bearings

- Can be made with a large or small ball design

- Ceramic hybrid design bearings are available upon request

- Ideal for high rigidity applications

OTHER STYLES OF PRECISION CYLINDRICAL PRODUCT INCLUDE COMBINATION PRODUCTS SUCH AS:

- Needle Roller Bearings

- Axial Cylindrical Roller Bearings

- Axial Radial Bearings

Need more information about bearings in the machine tool industry?

Contact us or give us a call 1-800-431-1980 and our experts will help find the best solution for your application.