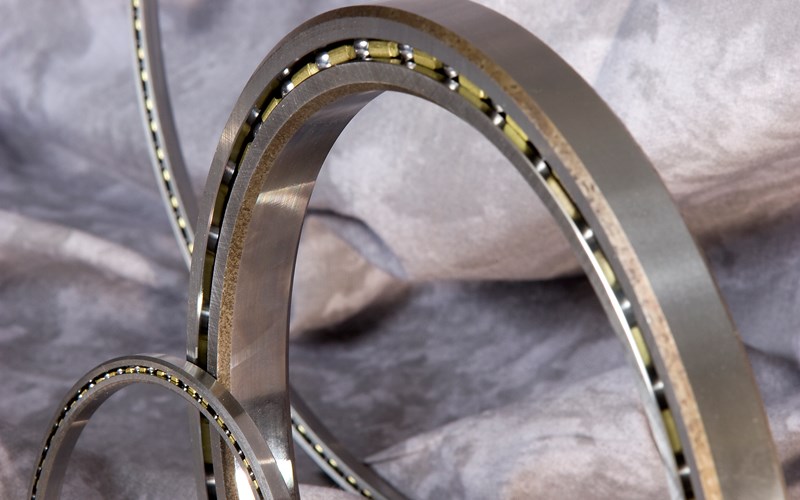

Bigger isn’t always better. Thin section bearings feature a compact design that works in tight spaces. This quality has led many businesses to learn more about how thin section bearings can benefit their applications.

As a bearing supplier we get many questions about the variety of bearings available. Here are some answers to questions people ask about thin section bearings.

WHAT ARE THIN SECTION BEARINGS?

As you may have guessed by the name, thin section bearings – also known as slim section bearings – are a type of bearing that is thinner than other options. This design creates a bearing that is very compact and lightweight.

WHAT ARE THE BENEFITS OF THIN SECTION BEARINGS?

The size and weight of the design are big draws for businesses in need of a bearing that can operate effectively in applications with very tight space limitations or weight concerns. Another advantage is that thin section bearings can be produced quickly, which is important for businesses that need bearing products right away without sacrificing on quality and performance.

ARE THERE DIFFERENT TYPES OF THIN SECTION BEARINGS?

Yes. There are few different styles of thin section bearings that can be used depending on the needs of your applications.

- Radial thin section bearings are used with predominantly radial loads.

- Angular contact thin section bearings are designed to handle higher thrust and axial loads.

- Four-point contact thin section bearings have a special raceway that creates four points of contact with the ball bearings so that the bearings can handle radial and thrust loads.

Thin section bearings also come in many other variations. These products can be made in many popular cross-section sizes. They can also be made with different materials (including standard steel, stainless steel, and chrome) and various seals for protection. Thin section bearings can also have specialized coatings applied to them such as Thin Dense Chrome plating or other a variety of other coatings.

WHAT APPLICATIONS OR INDUSTRIES ARE BEST FOR THIN SECTION BEARINGS?

Applications with space limitations commonly require thin section bearings. This can range from everything from textile machinery to missile launchers. Typical industries that use thin section bearings include:

- Food Processing

- Medical

- Machine Tool

- Satellite

- Packaging

- Robotics

- Military Turrets

- Material Handling

- Textile Machinery

- Optical Equipment

ORDER YOUR OWN THIN SECTION BEARINGS

Whether you know exactly what type of thin section bearing you need or if you need some guidance, we can help. Contact us to talk to one of our experts about standard or custom thin section bearings today.